In chemical manufacturing, where corrosive fluids, high temperatures, and stringent safety regulations define daily operations, choosing the right valve is critical. Among various flow control options, the non lubricated plug valve has become a trusted solution, offering a clean, low-maintenance, and leak-free alternative to traditional valves. These valves are ideal for high-purity and corrosive fluid applications, making them invaluable in chemical processing facilities.

What Is a Non Lubricated Plug Valve?

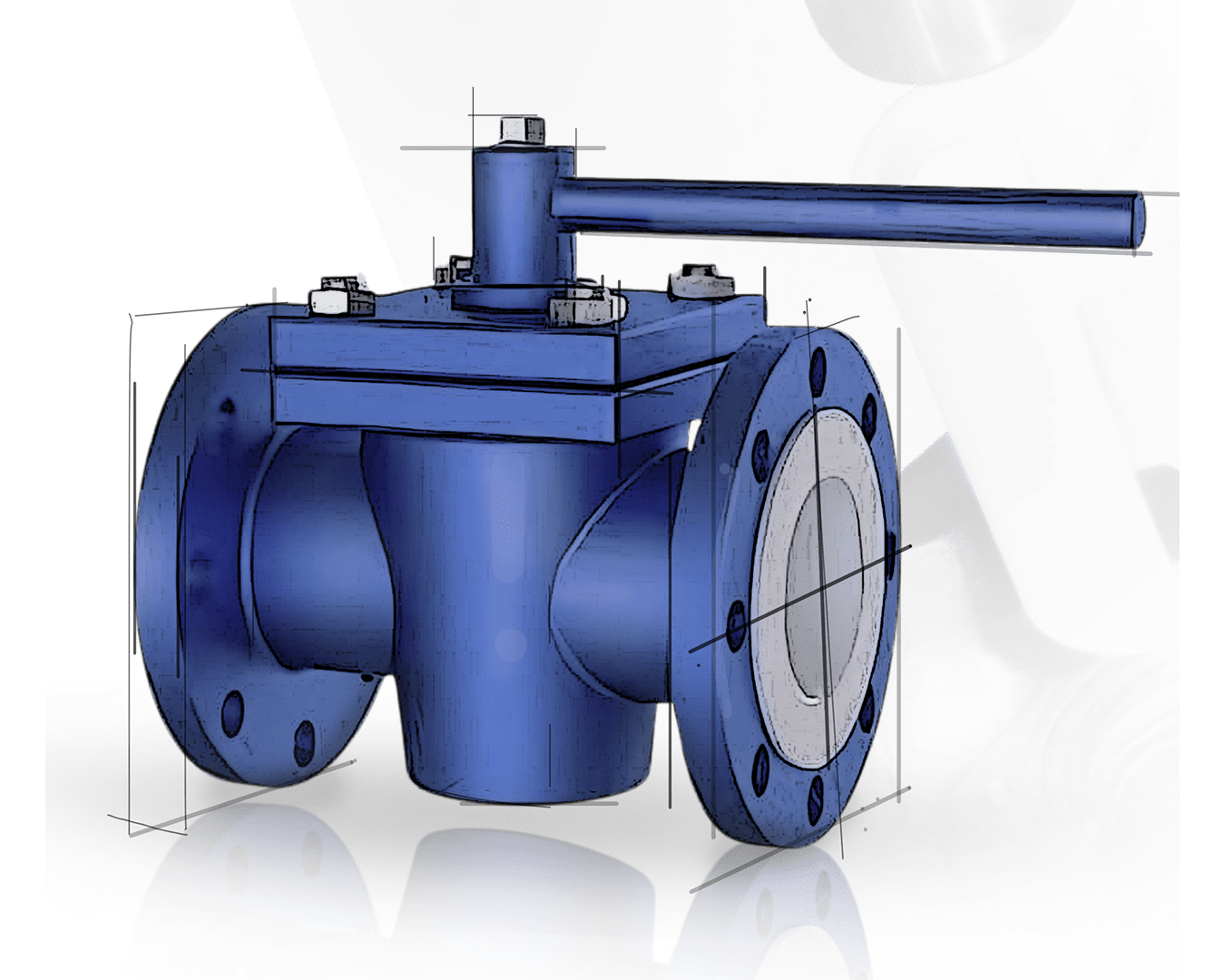

A non lubricated plug valve is a quarter-turn rotary valve with a tapered or cylindrical plug that controls the flow of fluids. Unlike lubricated plug valves, these valves use a sleeve (typically PTFE or other polymer) around the plug, eliminating the need for grease or oil. This design allows for smoother operation, better chemical resistance, and reduced risk of product contamination—an essential feature in the chemical industry.

Why Chemical Industries Prefer Non Lubricated Plug Valves

The benefits of using non lubricated plug valves in chemical plants include:

-

Zero grease contamination: No risk of lubricant leaching into the process stream.

-

Excellent corrosion resistance: Perfect for acids, alkalis, and other aggressive chemicals.

-

Low maintenance: No need for frequent lubrication or servicing.

-

Leak-proof shut-off: Minimizes the risk of leaks that could lead to hazardous spills or reactions.

-

Compact and durable: Designed for long-term performance even under tough conditions.

Key Applications in the Chemical Sector

Non lubricated plug valves are extensively used in:

-

Acid and base handling systems

-

Solvent transfer lines

-

Batch mixing and dosing stations

-

Effluent and waste treatment units

-

Chemical storage and distribution manifolds

In these critical areas, ensuring reliable shut-off and minimal contamination is essential—and non lubricated plug valves excel in meeting these standards.

SEO Long-Tail Keywords to Note:

-

non lubricated plug valve for chemical plants

-

PTFE sleeved plug valve for corrosive chemicals

-

chemical resistant plug valve manufacturers

Conclusion

For chemical processing units that demand precision, durability, and safety, the non lubricated plug valve is an indispensable component. Its maintenance-free operation and chemical resistance make it a top choice for enhancing operational efficiency and ensuring regulatory compliance.

Freture Techno Pvt. Ltd., a trusted non lubricated plug valve manufacturer in India, delivers premium quality valves designed for critical chemical applications, offering clients durable, leak-proof solutions tailored to their needs.