In various industrial systems where the control of fluid flow is crucial, plug valves play a key role. These valves are designed with a cylindrical or conically tapered plug that can be rotated inside the valve body to control flow. Due to their compact design, ease of operation, and quick shutoff capabilities, plug valves are widely used across a spectrum of industries such as oil and gas, water treatment, chemical processing, and power generation.

What Is a Plug Valve?

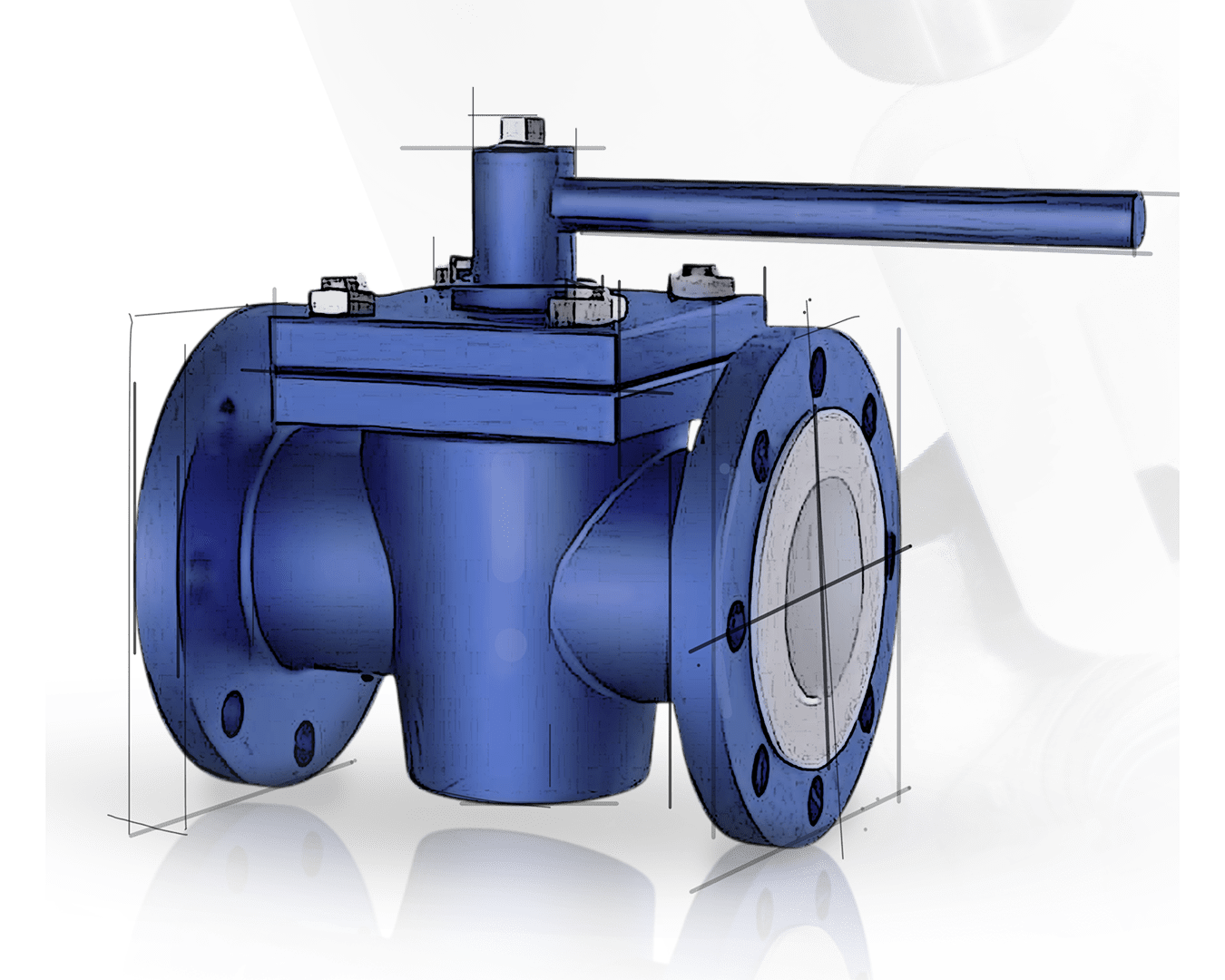

A plug valve is a quarter-turn valve that uses a plug with a hole to regulate the flow of fluids. When the hole is aligned with the pipe, the valve is open; rotating the plug by 90 degrees shuts the valve. Plug valves can be either lubricated or non-lubricated, and come in several types, including lift plug valves and expanding plug valves, each serving different process needs.

Key Features of Plug Valves

-

Quick operation with quarter-turn rotation

-

Minimal pressure drop

-

Compact and simple design

-

Tight shutoff capability

-

Suitable for slurries and viscous media

Industrial Applications of Plug Valves

🔧 Oil and Gas Industry

Plug valves are frequently used in upstream, midstream, and downstream operations due to their durability under high pressure and temperature. They handle crude oil, natural gas, and refined petroleum products efficiently.

🧪 Chemical Processing Plants

Their ability to withstand corrosive and abrasive fluids makes plug valves ideal for handling acids, alkalis, and other chemical compounds. They are often lined with PTFE or other corrosion-resistant materials.

💧 Water and Wastewater Treatment

Plug valves are employed in municipal and industrial water systems to control the flow of sludge, chemicals, and treated water. Their tight shutoff prevents leakage, which is critical for process reliability.

⚡ Power Generation

In power plants, plug valves manage the flow of steam, condensate, and cooling water. Their robust build and resistance to scaling and erosion make them a suitable choice in high-stress environments.

Types of Plug Valves

-

Lubricated Plug Valves: Suitable for high-pressure, high-temperature services.

-

Non-Lubricated Plug Valves: Require minimal maintenance; ideal for hazardous or corrosive environments.

-

Eccentric Plug Valves: Offer improved sealing in slurry and wastewater applications.

-

Expanding Plug Valves: Designed for zero leakage in critical service.

Lined Plug Valves ; A PTFE / PFA lined Plug valve is a specialized flow control device designed to regulate the movement of fluids through pipelines, particularly in industries handling corrosive or high-purity substances.

Advantages of Plug Valves

-

Simple to maintain and operate

-

Ideal for on-off and throttling applications

-

Effective in handling slurries and semi-solid media

-

Available in multi-port designs for more complex systems

Conclusion

From controlling aggressive chemicals in a plant to managing crude oil flows in pipelines, Plug valves serve as dependable components in a wide range of industrial processes. Their robust design, minimal maintenance, and excellent sealing capabilities make them a preferred choice for engineers and plant managers alike.

For industries seeking durable and reliable plug valves, partnering with a reputed valve manufacturer ensures longevity, performance, and compliance with industry standards.

No comments:

Post a Comment