In the oil and gas industry, the efficiency and safety of flow control systems are crucial for ensuring uninterrupted operations. Among the various valve types used across upstream, midstream, and downstream facilities, plug valves hold a special significance due to their robust design, quick operation, and ability to handle challenging service conditions. Their reliability in managing high-pressure, high-temperature, and corrosive flow media makes them a preferred choice for pipelines, refineries, and processing units worldwide.

Understanding Plug Valves in Oil & Gas Operations

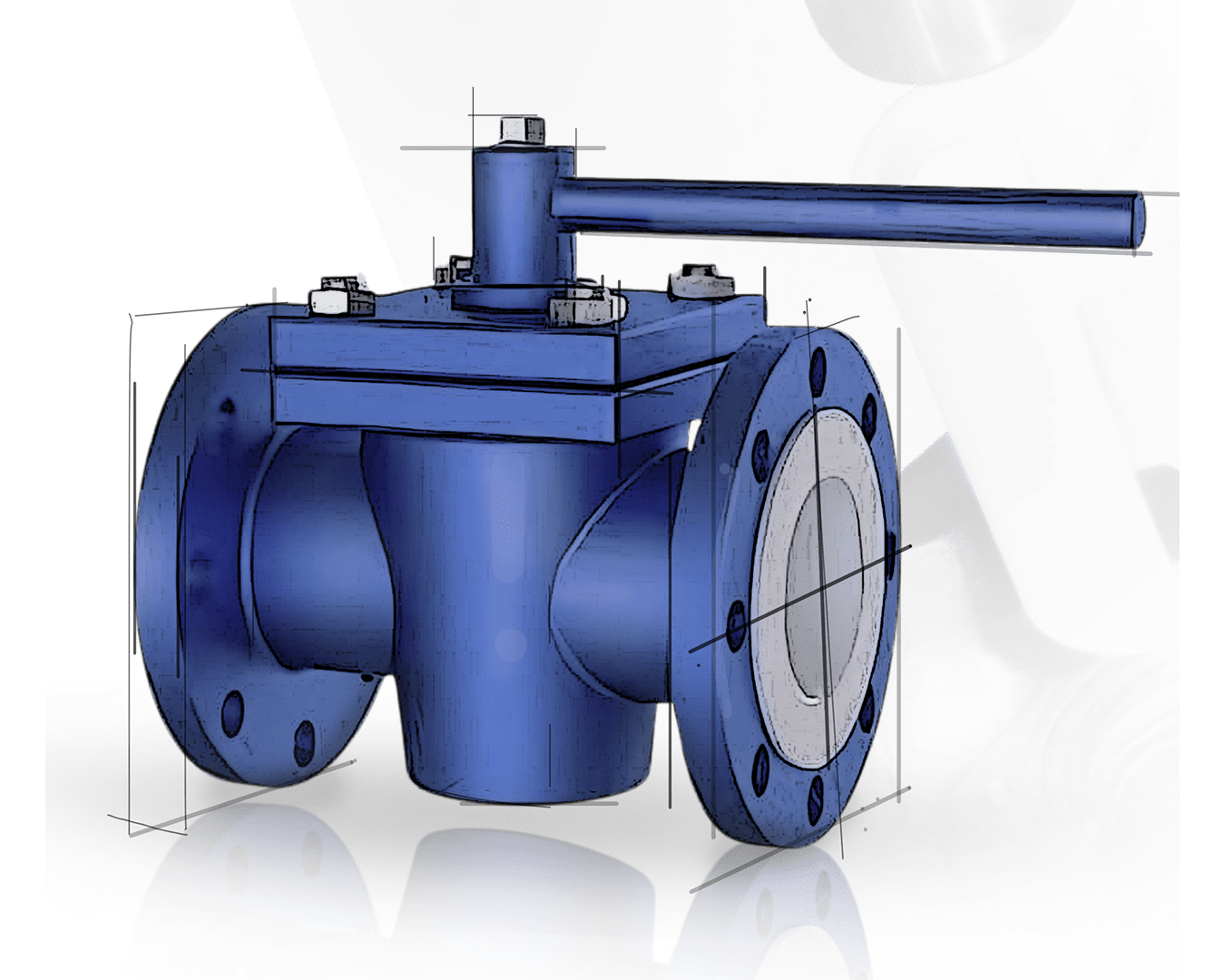

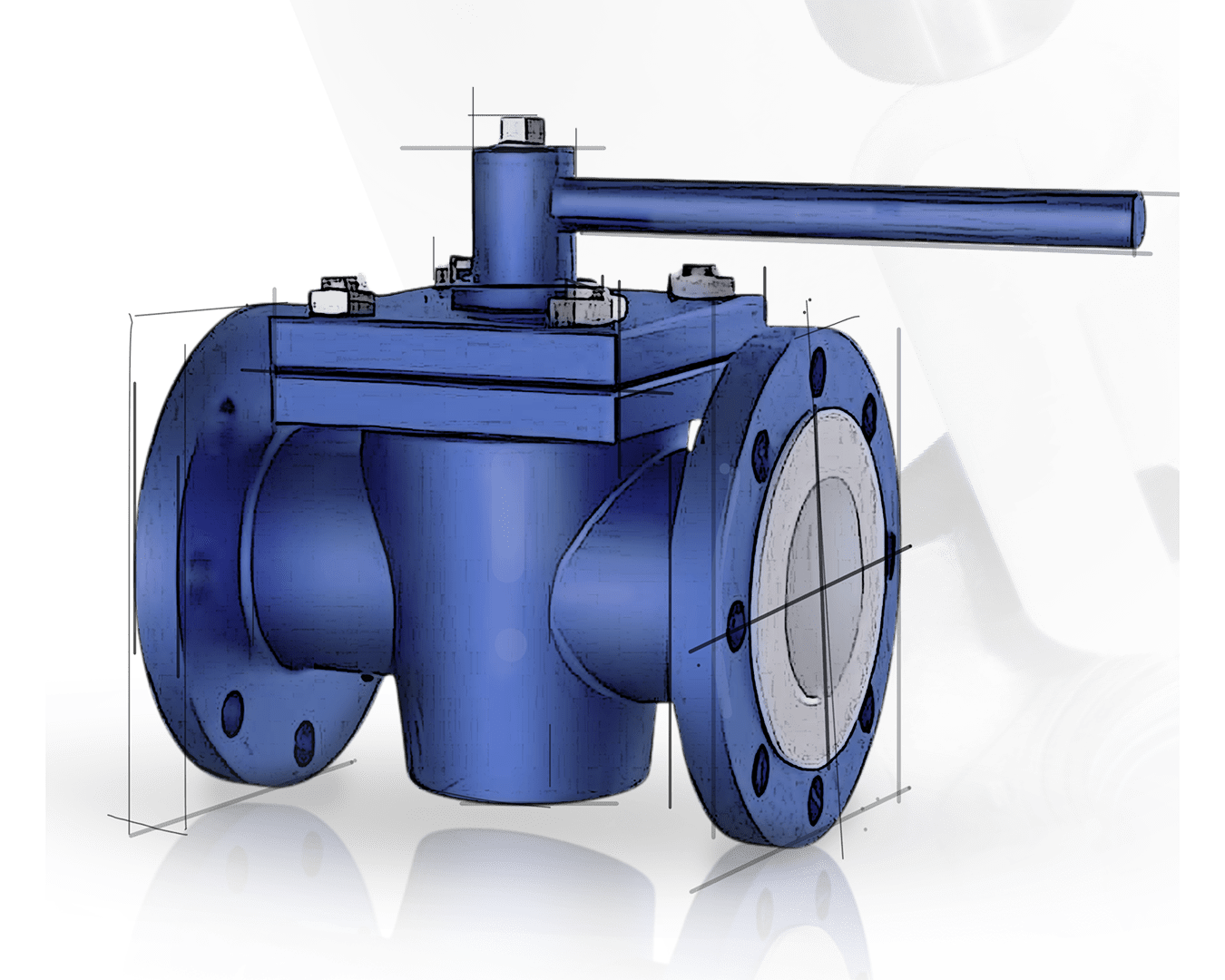

A plug valve is a rotary valve consisting of a cylindrical or tapered plug that rotates inside the valve body to regulate flow. The plug contains a port that aligns with the pipeline to permit flow and rotates a quarter turn to shut it off. This simple yet effective design enables tight sealing, quick operation, and dependable performance even in harsh environments.

In the oil and gas industry, plug valves are specifically valued for their ability to isolate flow rapidly, handle viscous or contaminated fluids, and perform reliably in emergency shutdown situations.

Why Plug Valves Are Important in Oil & Gas Applications

Oil and gas processes often involve abrasive slurries, dirty flow media, chemical-laden products, and fluctuations in temperature and pressure. Plug valves offer benefits that directly address these operational challenges:

1. Tight Shut-Off Capability

Non-lubricated and lubricated plug valves provide bubble-tight sealing, ensuring zero leakage—an essential feature in preventing product loss, contamination, or potential hazards.

2. Durability in Harsh Conditions

Plug valves can withstand corrosive fluids, crude oil with sediments, natural gas impurities, and high salinity environments, making them dependable across offshore and onshore facilities.

3. Quick 90-Degree Operation

Plug valves allow instant isolation during maintenance or emergency shutdowns, helping mitigate risks and ensuring personnel safety.

4. Suitability for High-Pressure Pipelines

Many plug valves used in the industry are designed to sustain high pressures without compromising sealing integrity or mechanical performance.

Key Technical Highlights

-

Quarter-turn design for fast operation

-

Available in lubricated and non-lubricated configurations

-

Designed for bi-directional flow

-

Can handle multi-port flow diversion (3-way or 4-way)

-

Metal or elastomeric seats based on service conditions

-

Excellent corrosion-resistant materials such as stainless steel, carbon steel, and alloy steels

These features collectively make plug valves versatile, strong, and capable of delivering long service life.

Challenges in Oil & Gas Processes Solved by Plug Valves

-

Handling Viscous or Dirty Media:

Plug valves perform efficiently in crude oil, slurries, and contaminated fluids where other valves may seize or wear out quickly. -

Reducing Leakage Risks:

Their reliable sealing minimizes fugitive emissions—a critical requirement in modern oil and gas regulations. -

Ensuring Smooth Flow Direction Control:

MultI-port plug valves simplify flow diversion in processing plants and manifold applications. -

Reducing Maintenance Downtime:

Lubricated plug valves are designed for easy maintenance, allowing operators to extend valve life without lengthy shutdowns.

Applications Across the Oil & Gas Value Chain

Upstream (Exploration & Production)

-

Wellheads

-

Drilling systems

-

Mud handling units

-

High-pressure manifold systems

Midstream (Transportation & Storage)

-

Crude oil pipelines

-

Gas transmission lines

-

Tank terminals

-

Pumping and compressor stations

Downstream (Refining & Petrochemicals)

-

Desalting units

-

Hydrocarbon processing

-

Fuel blending systems

-

Chemical injection lines

Across all segments, plug valves are essential for maintaining safety, flow integrity, and operational reliability.

Plug valves play a vital role in supporting safe, efficient, and stable operations in the oil and gas industry. Their robust design, ability to manage demanding flow conditions, and quick shut-off functionality make them indispensable across exploration, transportation, and refining applications. As industries push for more reliable and emission-free systems, plug valves continue to remain a trusted choice for engineers and plant operators seeking long-term performance and safety.